- Home

- Dive System

Dive System

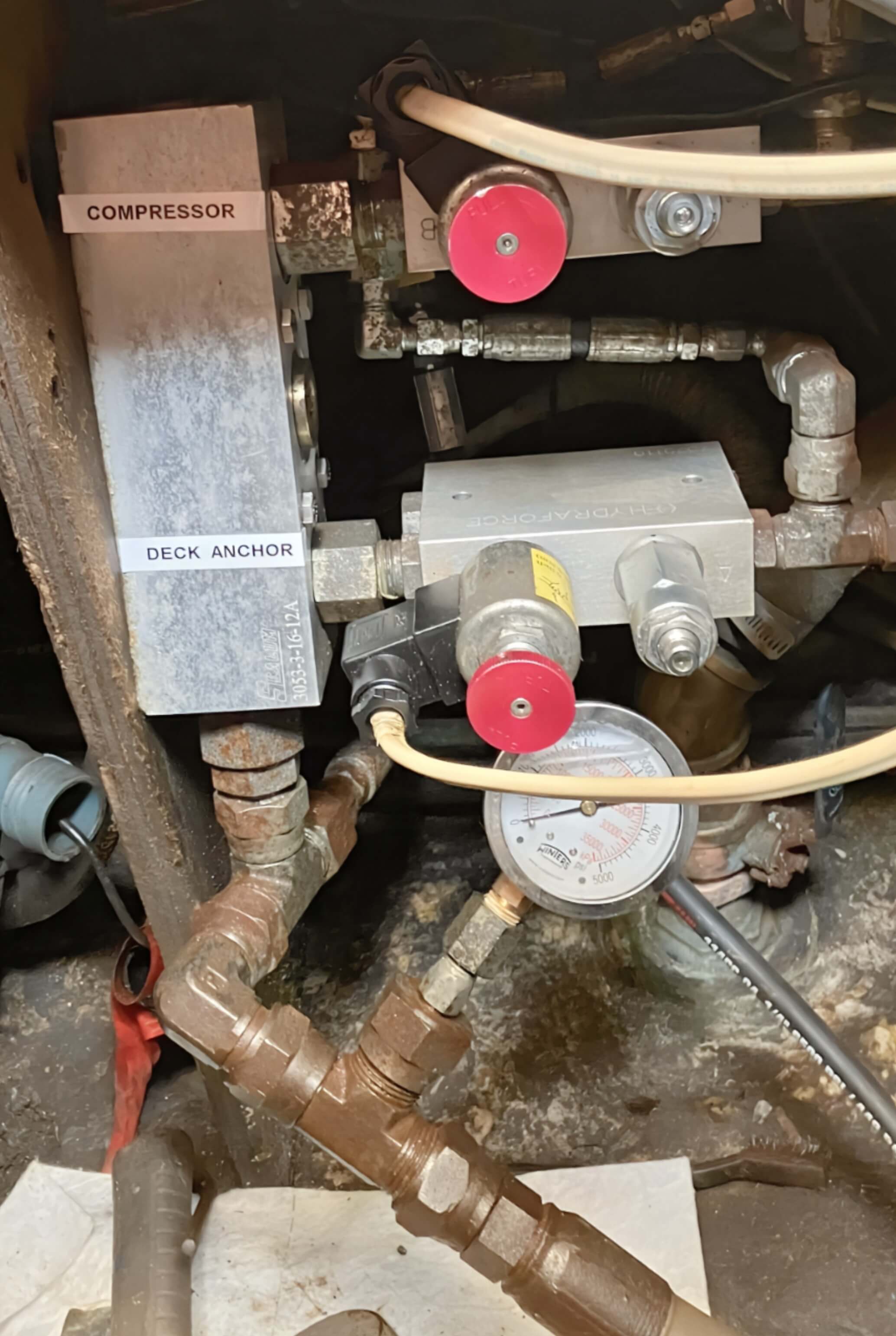

The Scuba Dive System consists of a Hydraulically Driven High Pressure Compressor System operated by 12 volt Solenoids. The main components are :

- Bauer K100 Dive Compressor.

- Hydraulic Motor.

- 12 volt Solenoid Switch (Hydraulic).

- Filter panel with Auto Shut Off.

- Scuba Tank Fill, Drain Cocks and Gauge.

1-Compressor

The Bauer K100 was purchased from Irwin Air in Surrey, BC. in 2014. It fills a standard 80 Tank in about 20 minutes. Bauer is a top of the line brand for breathing air compressors.

It's installed in the Engine Room, keeping it out of the weather and keeping the outer decks free of clutter.

2-Hydraulic Motor

The Hydraulic Motor running the Compressor is a 74111-DAF-01 Eaton Motor new in 2023. This is an expensive item (around $1500 cad) so I have the old one for a spare.

The old one ran perfectly for 10 years but developed a small oil leak during fishing season so a new one was purchased as I couldn't wait for it to be serviced.

3- 12V Solenoid Switch

A lot of Dive Boats in the industry use a Gas Engine to drive their compressors.

These are usually located on the back deck of the vessel, right in the elements of Canadian Winters including Rain, Wind and Waves. This can create havoc on these poor gas engines, trying to start them in such wet conditions.

This system uses a 12 volt solenoid to direct the flow of Hydraulic Oil to the Air Compressor, operated with a simple 12 volt switch.

4-Filter Panel

The Breathing Air Filter Panel is also located in the Engine Room. It includes:

- 2 Towers for Air Purification.

- Hoses to the Back Deck for Tank Filling and Moisture Dumping.

- 12 volt Automatic Shut Off Switch.

The Shut-Off stops the Compressor when the Scuba Tank has been filled to 3200 psi. This keeps the system from overfilling the Tanks, which can be dangerous and can shorten the lifespan of the tanks.

5-Tank Filling Station

The Scuba Tanks are Filled using a standard Filler on the Back Deck beside the Cabin Door.

There are 2 Moisture Dumping Valves, Pressure Gauge and a 12 volt Switch to turn on the Compressor.

When the pressure reaches 3200 psi. the Automatic Switch in the Engine Room overrides the Manual Outdoor Switch and stops the Compressor.

There are 5 Scuba Tanks included with the Boat. They all were Inspected and Hydro'd in May 2025.